GET HELP

Get in touch and let us know how we can help.

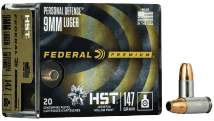

Product Inquiry

In-store sales questions and product inquiries.

Order, Account, and Transfers Inquiry

Online product inquiries, online orders, transfers, and shipping inquiries.

Gunsmithing and Sell My Gun Inquiry

Sell my gun, Glock blue label, gun cleaning, and gunsmithing questions.